How to bottle homebrew

No, I’m not kegging yet. After two solid years of brewing, I still haven’t yet carved out the space in the basement nor the acceptance of my wife to head down that road. I’ve got my process down for bottling and sanitization though. I can’t tell you how much I appreciate these basic rubber vinyl gloves. The way I’ve got my water heater set, my tap water gets to about 122* in the middle of winter. This can make it difficult to wash out bottles with full-on hot water without sorta burning my hands. I finally remembered this fact while on a grocery run and picked up a pair of tough vinyl brewing gloves like these.

No, I’m not kegging yet. After two solid years of brewing, I still haven’t yet carved out the space in the basement nor the acceptance of my wife to head down that road. I’ve got my process down for bottling and sanitization though. I can’t tell you how much I appreciate these basic rubber vinyl gloves. The way I’ve got my water heater set, my tap water gets to about 122* in the middle of winter. This can make it difficult to wash out bottles with full-on hot water without sorta burning my hands. I finally remembered this fact while on a grocery run and picked up a pair of tough vinyl brewing gloves like these. Amazing! I don’t have to burn my hands while washing bottles or get bleach all over them when cleaning out a fermenter.

My process for bottling is as follows:

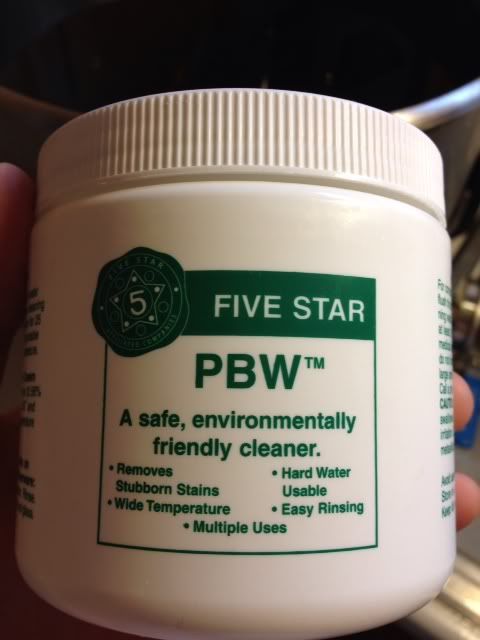

- Fill my brew kettle with about 8.5 gallons of 122* water while mixing in about 6 oz. of Five Star P.B.W.

- I can submerge about 28 bottles in solution at a time. I keep them under for 25 min. then rinse them out with hot tap water (and now wearing those brewing gloves!), then load them into the dish washer.

- I run the bottles through a normal wash cycle and let them steam dry.

- While the dishwasher is doing its work, I’ll be taking about 4 oz. of priming sugar

and boiling it in a pint of water for 10 min., then cooling that water to roughly the temperature of the fermented beer (either by placing it outside in the winter or by partially submerging the small boiling pot in the sink with a small amount of ice water.

- Once cooled, I’ll take that sugar water solution and dump it through a sanitized funnel into the secondary fermenter still containing the fermented beer.

- Once the dishwasher is nearly done running and drying the bottles, I’ll syphon the batch from the secondary fermenter into a bottling bucket, using my 5 gal. kettle top to keep a lid on things. Adding the sugar water to the secondary fermentor and then syphoning it all into the bottling bucket gives the sugar water plenty of opportunity to mix with the beer without the need to stir the batch (which you want to avoid at all costs at this stage as stirring will cause the beer to pick up oxygen, oxidize and create off-flavors reminiscent of wet cardboard).

- To bottle, I’ll place the bottling bucket over the opening for the dishwasher so I don’t have to clean up any spills, as they’d drip right into the opened door of the dishwasher.

- Pull a bottle out at a time, fill it slowly, top it with a sanitized cap and let it sit on the table un-capped while I bottle the rest of the batch. I don’t cap the bottle immediately because I want the CO2 released by initial fermentation of the sugar solution to push some (preferably all) of the oxygen in the head space of the bottle out of the bottle before it’s capped.

- Once I have all the bottles filled and topped, I’ll cap them and mark the caps using a sharpie with whatever initials I’m going to use to identify that batch. These caps

I use are pretty cheap, so buy a bunch of different colors so I can switch up the color of the caps from batch to batch and identify a batch of beer at a glance in my cellar.

Bottling a lager is a little different than an ale, because most of the yeast needed to bottle-condition has dropped out of solution during the lagering stage of the process that has just completed prior to bottling. To combat this, I take about 1/4 to 1/2 packet of dry yeast (most recently I used Saflager S-23), and add it to 8 oz. of boiled and cooled water, let sit for about 15 min. then add a few ounces of the sugar water solution prior to adding it to the secondary fermenter. After 10 minutes more or so, I’ll add that yeast/sanitized water/sugar water solution to the secondary before syphoning everything into the bottling bucket.

The entire bottling process probably takes me around 4 hrs. for ales and maybe 5 for lagers. It’s almost like another brew day, just with less cleanup. I would really like to get into kegging to save hassle here, especially in pursuit of producing exemplary lager beer. Some day…

Pingback: Bottling the smoked lager « Barking Dog Beer