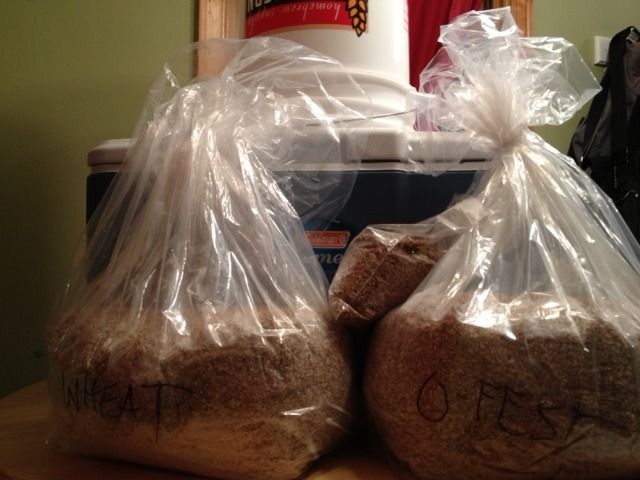

Fraz(zled) Wheat 3.0

Back by popular demand for the third year in a row, I crammed in a double brew day back in May so I could have some Fraz(zled) Wheat raspberry hefeweizen on hand for the coming summer months. Though last year’s 2.0 version didn’t do so hot in competition (“too much raspberry flavor overpowers the base style”), it sure was greatly appreciated by anyone who was able to snag a bottle. This is the only seasonal brew I’ve done each year I’ve been brewing, starting off as an extract version in 2010, moving to all-grain in 2011 and of course again this year as well.

Back by popular demand for the third year in a row, I crammed in a double brew day back in May so I could have some Fraz(zled) Wheat raspberry hefeweizen on hand for the coming summer months. Though last year’s 2.0 version didn’t do so hot in competition (“too much raspberry flavor overpowers the base style”), it sure was greatly appreciated by anyone who was able to snag a bottle. This is the only seasonal brew I’ve done each year I’ve been brewing, starting off as an extract version in 2010, moving to all-grain in 2011 and of course again this year as well.

I tried a new base hefeweizen recipe for Fraz Wheat this year, taken directly from the book Brewing Classic Styles by John Palmer and Jamil Zainasheff:

Fraz(zled) Wheat |

|||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||

I decided to collect a little extra wort from the mash tun compared to normal and do a split batch, as I’d received feedback last year that I should do a non-raspberry version / a normal hefeweizen as well. Taking that to heart, I syphoned half the wort (3.5 gal.) into one smaller secondary carboy and the other half into another, figuring the secondaries would be better than a primary so as to reduce the headspace (granted, less headspace is not as important of a consideration during primary fermentation).

I decided to collect a little extra wort from the mash tun compared to normal and do a split batch, as I’d received feedback last year that I should do a non-raspberry version / a normal hefeweizen as well. Taking that to heart, I syphoned half the wort (3.5 gal.) into one smaller secondary carboy and the other half into another, figuring the secondaries would be better than a primary so as to reduce the headspace (granted, less headspace is not as important of a consideration during primary fermentation).

I did the same thing with the 1600 ml yeast starter, splitting it in between the two carboys. I perceive the carboy with the black brew hauler attached received slightly more yeast than the one with the red handle. This made sense when the billowy head of yeast typical of hefeweizen strains blew out the airlock on the carboy with slightly more yeast than the other (while the other was very close to necessitating blow-off tubing).

In pursuit of limiting opportunity for oxidation, I simply left each of these in their respective fermenters for two solid weeks. I syphoned the normal hefe to the bottling bucked and bottled two weeks after brew days. On the same day I bottled, I pasteurized 32 oz. of frozen raspberries using the same method employed for my cherry stout last fall (which may be overkill, as the alcohol in the beer would probably protect the batch from infection at this point anyway) and tossed them into the “primary” (remember, it’s actually a “secondary” vessel being used as a primary) fermenter and let the beer go through another mini-fermentation of the raspberries over the course of the next week.

Pre raz:

Post raz:

This year I combined using real raspberries (however, less by volume than last year so they’re not as overpowering to the base style) with 1.5 oz. of raspberry extract syrup. The real raspberries will, once fermented in solution, provide a tart fruit flavor to the brew while the extract syrup will provide definitive raspberry aroma to the batch. Since a large part of taste is smell, I’m hoping the combination of raspberry aroma and a (restrained) tartness derived from real raspberries will yield positive results.

This year I combined using real raspberries (however, less by volume than last year so they’re not as overpowering to the base style) with 1.5 oz. of raspberry extract syrup. The real raspberries will, once fermented in solution, provide a tart fruit flavor to the brew while the extract syrup will provide definitive raspberry aroma to the batch. Since a large part of taste is smell, I’m hoping the combination of raspberry aroma and a (restrained) tartness derived from real raspberries will yield positive results.

The weekend after bottling the basic hefeweizen portion of the batch, I purchased a keg and used the raspberry portion of the batch to try my hand at kegging for the first time. I definitely learned a lot about a whole new facet of brewing that weekend (while also wasting a lot of Co2, I suppose). I also bought a Blichman counter-pressure beer gun so I could still fill bottles with pre-carbonated beer directly from the keg (mainly to be used in competition). Here’s Midwest Supplies’ version of the beer gun..

It’s cool to have CO2 on hand now for purging fermentation vessels too. I did this on the Osktoberfest as I transferred it to a “secondary” vessel, which actually ended up being a primary-sized caryboy because the batch would be too large to fit into a true secondary. Hopefully I can ward off potential oxidation if I am purging fermentation vessels and bottling off a keg with the counter-pressure bottle filler. This was a costly investment but hopefully it can help me score higher in competition over time, and make great beer to drink too, I suppose.