Private tour of Goose Island's production brewery

Recently I was able to go on a private tour of Goose Island’s production brewery led by their communications coordinator, Ken Hunnemeder. Goose’s flagship brewery is located not far from their corporate offices and just a few miles from their Clybourn brew pub I toured a year ago. It was an extremely hot 100+ degree day outside and of course inside the brewery it was much warmer. I bet if Goose does protein rests on their mash they probably didn’t even have to heat the water on the day of my tour. Room temp would have sufficed. HA!

Recently I was able to go on a private tour of Goose Island’s production brewery led by their communications coordinator, Ken Hunnemeder. Goose’s flagship brewery is located not far from their corporate offices and just a few miles from their Clybourn brew pub I toured a year ago. It was an extremely hot 100+ degree day outside and of course inside the brewery it was much warmer. I bet if Goose does protein rests on their mash they probably didn’t even have to heat the water on the day of my tour. Room temp would have sufficed. HA!

Before walking around the facility I was able to try a few beers they had on tap for tasting. Most notable was the latest in the Fulton & Wood series, Black Mission. They definitely hit the mark with Black Mission in an attempt to recreate the flavor of a fig newton, though that doesn’t mean you should necessarily consider this a dessert beer. It had a dry finish and subtly spicy hop profile so as to work well with fattier meats like duck or lamb. The beer’s base malt bill is that of a Vienna lager, which makes sense when you taste all the caramel flavors from Vienna and Munich malts in this beer. The other sample I tried was Sofie, their saison. Though I’d had it before, I still reached for Sofie knowing this crisp citrusy Belgian ale with a hint of spice was perfect for accompanying the sweaty brewery tour ahead.

We began by meeting Brewmaster Brett Porter, Senior Brewer John J. Hall and a third guy new to the brewing staff whose name I can’t recall. Next we checked out the user interface that allows brewers to move hundreds of gallons of wort around the brewery. I learned their largest fermenters take between five and nine “turns” to fill, which means they’re running that many consecutive batches through their mash/lauter/boil process before the fermenter is full.

We moved on to the lower level, where we got to see the mash tun and how every phase of wort production is connected. Next was the fermenters. The most indicative illustration of Goose Island’s production output ability was the size not of their largest fermenters, but rather of what on a homebrew scale we’d refer to as their “yeast starters.” You’ve probably seen 15bbl fermenters setup in brew pubs. Well, Goose has at least three of those fermenters set up purely to grow yeast! Just yeast! For some perspective, consider that when I make a yeast starter at home, it’s 2,000 ml. Ken explained that the high pitching rates they use allow them to ferment and produce beers like 312 Urban Wheat in as little as eight calendar days (yeast work over the weekends too).

Here’s underneath the lauter tun:

In this pic you can see on the left the smaller “yeast starter” fermenters next to much larger fermenters for actual batches of beer:

Ken led me by the barrel room where we saw brewer John Laffler hard at work cleaning, prepping and organizing barrels late on a Friday afternoon. As a brewer, John’s whole focus is on barrel aging. It’s amazing they’re able to have members of their brewing team that focused on a single aspect of the business. Quality and consistency are of the utmost importance here as in any good brewery, but Goose puts their money where their mouth is and is able to have specific brewers devoted to coordinating certain niche aspects of their portfolio of beers. Pretty damn cool. Must be a fun place to work as a brewer.

We saw the old smaller (yet still quite large) horizontal tank where Matilda is fermented by wild yeast and bacteria as well as the newer, much larger horizontal Matilda fermenter funded through the InBev buyout of 2011. The one you see in the pic below is the old, smaller Matilda tank:

We then hit up the experimental brew house where Fulton & Wood series brews like Black Mission, En Passant and Old Town Yard were conceived. In this same room is the mini-brew house utilized by the Siebel Institute, one of the nations two premier brewing schools. Siebel used to run their hands-on brewing tutorials at Goose’s Clybourn brew pub but have since expanded that operation a bit and moved to this production facility.

Ken took me through bottling, packaging and receiving. He noted Goose would soon be investing in more equipment to handle 750 ml bottling for their vintage ale series and perhaps others.

We walked past the quality control testing lab where they run samples of beers through various regimes both before and after they are released to market, the latter of which allows Goose Island to know whether or not their products are aging gracefully on the shelves. Ken cited one instance a few years ago where a particular batch of Matilda became infected with Lactobacillus which soured the beer much more than intended. As a sour beer fan, he noted it tasted phenomenal yet it wasn’t exactly “Matilda” so whatever could be located still on the shelves was recalled. That particular batch (as indicated by the batch number printed on the bottle) became a highly prized possession for beer collectors and sour beer fans alike.

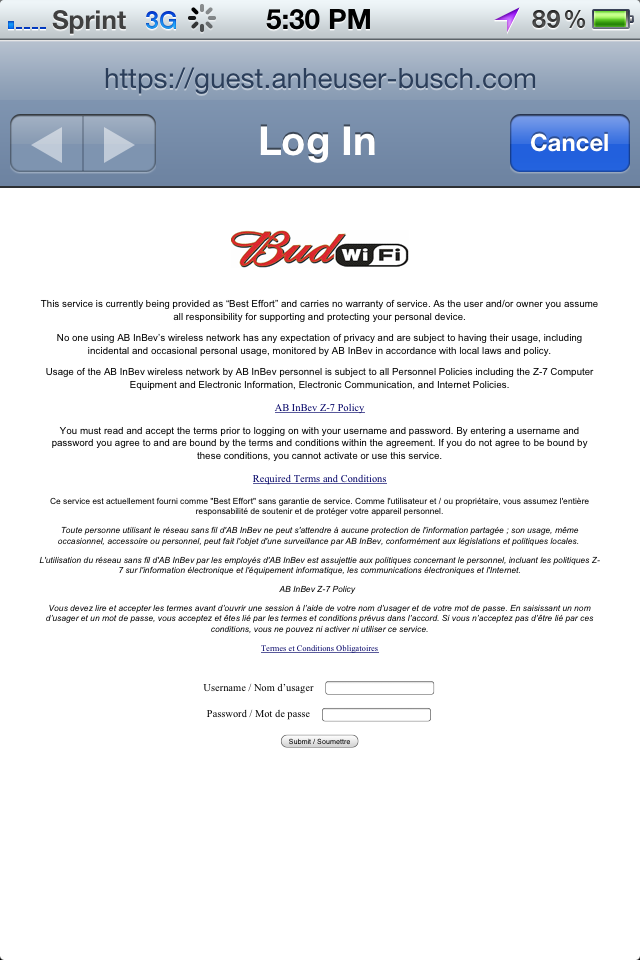

I was quite impressed with the size, complexity and attention to detail taken at every step of operations at Goose. I will note that besides the enormous tank installed to ferment Matilda, I didn’t see any specific telltale signs of InBev’s purchase of Goose Island. Well, besides the WiFi:

The behind-the-scenes nature of this tour made it the best brew tour I’ve taken thus far, knocking Lakefront Brewery from my #1 spot it had occupied since 2005. Thanks to Ken and everyone I met at Goose Island for the opportunity to check out their impressive facility!

Where the marketing magic happens!