First batch of cider

Inspired by a recent cider-centric BrewingTV episode, I managed to get a contact through my homebrew club in September for some homemade cider. The guy has seven apple trees in his Victoria, MN backyard and had pressed the cider the very same day I picked it up, drove home and began the fermentation process. Can’t get much fresher than that! $25 for 5 gallons. Happy to pay that price, especially because the guy made it himself. The batch I picked was a blend of Macintosh and Prairie Spy apples.

Inspired by a recent cider-centric BrewingTV episode, I managed to get a contact through my homebrew club in September for some homemade cider. The guy has seven apple trees in his Victoria, MN backyard and had pressed the cider the very same day I picked it up, drove home and began the fermentation process. Can’t get much fresher than that! $25 for 5 gallons. Happy to pay that price, especially because the guy made it himself. The batch I picked was a blend of Macintosh and Prairie Spy apples.

I hadn’t done much research on making hard cider prior to the BrewingTV episode and was pleasantly surprised at how easy this is compared to all-grain (and even extract) brewing. No boiling involved! Here’s the process:

- Aerate the cider (all the sloshing during the 45 min. drive home was sufficient for aeration, I assume)

- I added 3 cups of sugar (1 brown, 2 white) to boost the gravity and flavor complexity. My OG was 1.060 after adding the sugar. I didn’t take it prior to this addition but read that cider is often in the 1.040’s without adulteration.

- Pitch 5 campden tablets (1 per gallon) to kill off any wild yeast existing in the cider, which is most certainly there. If you wanted to take a bit of a gamble and potentially come out with a “sour” or “wild” cider, you could skip this step. As in any sour fermentation, make note that this will take much longer to complete and you’ll now have introduced wild bacteria into your equipment and may want to keep plastic components that come into contact with the beer permanently separate from your “clean” beers (or ciders) you ferment in the future.

- Wait 12 hours (or longer if this doesn’t fit your schedule).

- Pitch 2.5 tsp pectic enzyme (1/2 tsp per gallon).

- Wait 12 more hours (or longer if this doesn’t fit your schedule). I will probably wait a total of 48 hrs. from campden pitch to yeast pitch when I do this again next fall, just to give the campden enough time to off-gas and not hinder the yeast I pitch.

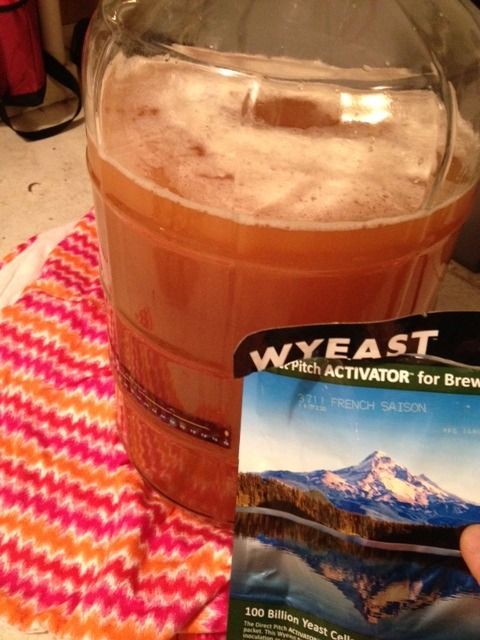

- Pitch yeast (1 pack is fine, as cider is all easily digestible simple sugars, no starter necessary) and 1/2 tsp yeast nutrient (I didn’t re-hydrate it but suppose you could). I used Wyeast 3711 French Saison instead of a traditional cider yeast upon recommendation of the Northern Brewer sales associate. He’d done this before and said it produced an incredibly complex cider. Hey, I like saison and I like cider. Hopefully they go well together!

- Wait for a long time! It took nearly two days to see any activity. Repeat: “any” activity. I was worried I’d pitched too soon after the campden tabs, but everything eventually took off. It’s been 20 days since pitch as I write this, and while the krausen dropped after roughly three days of active ferment (5 days after pitch), the airlock has been bubbling consistently ever since. I almost thing this will never stop fermenting! I think I’m going to transfer to secondary this weekend, which will be 23 days since pitch and 21 days since active fermentation began.

The guy who sold me the cider keeps some to ferment for himself as well. We shared a bottle from last year. Some people back-sweeten their ciders to bring some body back into the cider and make it less dry, as the nature of simple sugars in cider allows it to ferment below 1.000 FG. This guy does not back-sweeten, and I don’t think I will either. His cider was delicious and effervescent! Almost like apple-flavored champagne. Loved it. Also, If you don’t back-sweeten, you don’t have to worry about keeping the batch cold to prevent further fermentation (and if bottled, bottle bombs). His was brilliantly clear as well and I had him explain his conditioning process. He ferments in the fall and lets it sit all winter, transferring from secondary to secondary a few times to get the batch off any residual yeast, then bottle-conditions in the spring. I won’t be able to wait that long, thinking I may have this as my holiday brew this year.

The guy who sold me the cider keeps some to ferment for himself as well. We shared a bottle from last year. Some people back-sweeten their ciders to bring some body back into the cider and make it less dry, as the nature of simple sugars in cider allows it to ferment below 1.000 FG. This guy does not back-sweeten, and I don’t think I will either. His cider was delicious and effervescent! Almost like apple-flavored champagne. Loved it. Also, If you don’t back-sweeten, you don’t have to worry about keeping the batch cold to prevent further fermentation (and if bottled, bottle bombs). His was brilliantly clear as well and I had him explain his conditioning process. He ferments in the fall and lets it sit all winter, transferring from secondary to secondary a few times to get the batch off any residual yeast, then bottle-conditions in the spring. I won’t be able to wait that long, thinking I may have this as my holiday brew this year.

Very excited to try and share this when it’s complete!

High krausen, 3 days after pitch and 1 day after onset of active fermentation, the majority of fermentation was at 69-70*

Let me know when it’s ready. I’ll be happy to help you evaluate your efforts.

October 10, 2012 at 9:27 am

Will do!

October 10, 2012 at 11:01 am