I bottled my California Common steam beer back on 3/31 (Golden Gate Retriever) and cracked the first bottle three weeks later. I think it was a bit early, as I thought I sensed a trace amount of acetaldehyde green apple flavor. I haven’t had a problem with this off-flavor much in the past. Acetaldehyde is usually found in beer that was racked from primary fermentation too early, not giving the yeast time to clean up this off-flavor they create during the process. I looked back at my fermentation schedule and it was in primary for 20 days (plenty of time!) at temps of 55-58*, which I’d think would be the culprit if this weren’t fermented with WLP-810 San Francisco lager yeast. In reading the description on White Labs’ site, I guess they say the optimum fermentation temp for this strain is 58-65*, so I might have been a bit under the optimum fermentation temp which may have inhibited the yeast from cleaning up after themselves…

I bottled my California Common steam beer back on 3/31 (Golden Gate Retriever) and cracked the first bottle three weeks later. I think it was a bit early, as I thought I sensed a trace amount of acetaldehyde green apple flavor. I haven’t had a problem with this off-flavor much in the past. Acetaldehyde is usually found in beer that was racked from primary fermentation too early, not giving the yeast time to clean up this off-flavor they create during the process. I looked back at my fermentation schedule and it was in primary for 20 days (plenty of time!) at temps of 55-58*, which I’d think would be the culprit if this weren’t fermented with WLP-810 San Francisco lager yeast. In reading the description on White Labs’ site, I guess they say the optimum fermentation temp for this strain is 58-65*, so I might have been a bit under the optimum fermentation temp which may have inhibited the yeast from cleaning up after themselves…

Fortunately, the yeast appear to be cleaning up the small amounts of acetaldehyde in the bottle over time. The green apple flavor has dissipated over the past week of bottle conditioning since I opened the first bottle. It’s getting clearer at lower temperatures too. This drinkable 4.5% brew will be one of the two I may compete in my brew club’s summer <6% beer competition. We’ll see if it’s better than the Belgian Pale Ale I’m working on, which should clock in at 5.5%. Read the rest of this page »

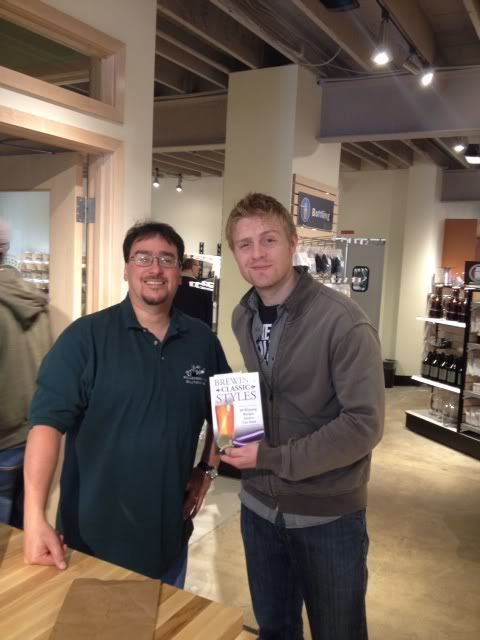

I met John Palmer last weekend, author of

I met John Palmer last weekend, author of

I threw together a brew day at the behest of the wife this past weekend as she was going to be busy with other stuff. Not a problem! I just moved up my plans to brew a Belgian pale ale by a few weeks (named after a popular Belgian sheep dog, the

I threw together a brew day at the behest of the wife this past weekend as she was going to be busy with other stuff. Not a problem! I just moved up my plans to brew a Belgian pale ale by a few weeks (named after a popular Belgian sheep dog, the  That’s ok, I get it. Just thought I’d try. I took another avenue and listened to a podcast by Jamil Zainasheff from 2006 where he walks through his own BPA recipe (

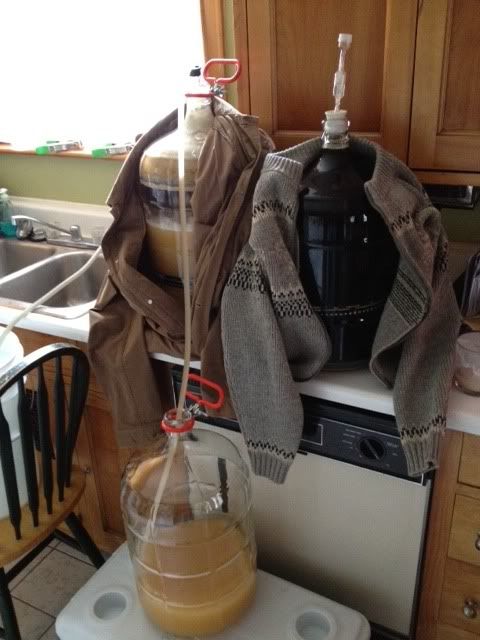

That’s ok, I get it. Just thought I’d try. I took another avenue and listened to a podcast by Jamil Zainasheff from 2006 where he walks through his own BPA recipe ( To complete primary fermentation on

To complete primary fermentation on  I was able to procure two bottles of Surly 5 when it went on sale last September and have been hoarding them since. Since I brewed my wort contribution to

I was able to procure two bottles of Surly 5 when it went on sale last September and have been hoarding them since. Since I brewed my wort contribution to  In a recent post, I discussed how members of the Nordeast Homebrewers Club are doing a sour beer project. Since my schedule will be a bit cramped in the coming weeks with the new baby, work and gigs with my band, I decided to get this brew done ASAP on 3/25 so I could ensure I’m ready to transfer this into the barrel along with everyone else’s beer near the end of April.

In a recent post, I discussed how members of the Nordeast Homebrewers Club are doing a sour beer project. Since my schedule will be a bit cramped in the coming weeks with the new baby, work and gigs with my band, I decided to get this brew done ASAP on 3/25 so I could ensure I’m ready to transfer this into the barrel along with everyone else’s beer near the end of April.